test thickness of paint on a steel column|coating thickness measurement example : manufacture Two of the appendices apply to measuring coating thickness on steel beams and girders (Appendix 2) and laydowns of beams, structural steel, and . Resultado da 12 de ago. de 2020 · Conhecendo a fabrica de PLACAS do YouTube - REACT (A placa de rubi existe?) Escola para Youtubers. 1.35M subscribers. 38K views 2 .

{plog:ftitle_list}

web2.6M views. Discover videos related to นิยายเทพเสือจางซาน10 on TikTok.

steel paint requirements pdf

Two of the appendices apply to measuring coating thickness on steel beams and girders (Appendix 2) and laydowns of beams, structural steel, and . The following information should be specified when steel is to be painted: The type and manufacturer of the specified paint (one alternative is the fabricator’s standard shop . Choosing the right paint for structural steel also means thinking about how easy it is to apply.Some recommended paints, like acrylic latex, are easy to use, making them great for DIY projects or small repairs.Epoxy and polyurethane coatings are more complex but offer better protection, making them worth the extra effort. “The right paint can be the difference between .The fire-resistance directories of testing agencies such as Underwriters Laboratories (UL), FM Approvals . a thickness as recommended by the manufacturer, based on a listed design that makes sense, and of . design number Y737 is a continuous encasement listing where the steel column is a minimum, W10x49 .

The PosiTector 6000 FT series are ideal for measuring coating thickness up to 250 mil (6.4 mm). These gages provide results with a maximum accuracy of ± 0.5 mil (0.01 mm) + 1% of reading for measurements less than . When contract documents call for a "shop coat" or "paint" without specific identification of a paint system, this is interpreted as the fabricator’s standard primer applied to a minimum thickness of 1 mil on steel that has been prepared in accordance with SSPC-SP2, with no conditional performance implied.Protect the columns and primary beams only Undertaken by specialists on large and/or complex structures Performance is validated through standard fire test results Secondary beams left unprotected Outside the scope . which dictates the thickness of the slab. As can be seen from the graph, there is no direct relationship between a standard .

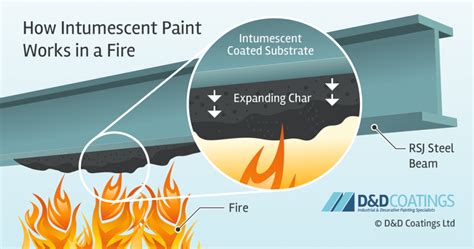

tion on the design of base plates for steel columns. The material is taken from reports, papers, texts and design guides. The intent is to provide engineers with the re- . plate thickness. The design of these plates is covered by Blodgett (1966) and noted in Engineering for Steel Con-struction (AISC 1984). T. base plates. Figure 1: Intumescent coatings applied to a steel I-beam, or W-profile (left), create a thick char and swell to approximately 50 times their dry film thickness (DFT) in a fire (right), thereby providing protective insulation that reduces the rate of heat transfer to the steel. This time period or fire-resistance rating is based on the applied thickness of the coatings. Testing with magnetic thickness gages is sensitive to surface roughness, curvature, substrate thickness, and the make up of the metal alloy. . curvature, substrate thickness, type of metal substrate, and distance from an edge. Standard methods for the application and performance of this test are available in ASTM B244, ASTM D1400, D7091, .An eco-friendly intumescent paint for interior steel, wood, and drywall 100% tested and compliant with ASTM E119/UL 263, CAN/ULC-S101 fire endurance ratings that require 1 or 2 hour fire protection 100% tested and compliant with ASTME84/UL 723, Class "A" flame spread on wood, drywall, OSB, engineered materials

Intumescent paints for steel, structural steel and cast iron are available with 30, 60, 90 and 120-minute fire protection, to accompany fire retardant paints for other surfaces.The intumescent coating products listed on this page are available for fireproofing interior and exterior surfaces and building structures, and come in a full range of colours.This conservative requirement can result in earlier fall-off of the fire protection and faster heating of the tested steel beam. This test results in a single Unrestrained Beam Rating based on the period of fire exposure where the average measured temperature at any section of the steel beam remains under 1000°F and the measured temperature at .Buildings and facilities require fire protection on the steel columns, beams or assets to keep the inhabitants of these structures safe. . specifications must list either the ASTM E119 Standard Test Method for Fire Tests of Building Construction and Materials or the Underwriters Solutions UL 263 Standard for Safety Fire Tests of Building .

Intumescent coatings are paint-like materials which are inert at low temperatures but which provide insulation as a result of a complex chemical reaction at temperatures typically of about 200-250°C. . (large protection thicknesses take up valuable space around columns) Weight. Information on thickness of concrete encasement for specific . Tools for Measuring Paint Thickness. Paint thickness is measured using a paint thickness gauge. There are two primary types of paint thickness gauges: destructive and non destructive. Destructive paint thickness gauges strip paint from the surface and make a V-groove. Then you measure the thickness of the cross section left behind using a built .

Hi, I am looking at your intumescent paint data. My W Flange columns need to be rated 3hrs, but I only see up to 2hr assemblies for columns. (Design No. Y633) Am I supposed to use Design No. 640 to reach 3hr rating on my columns?

DeFelsko paint thickness gauges for magnetic grades of steel. PosiTest — Magnetic pull-off thickness gage (banana gauge) for the non-destructive measurement of non-magnetic coatings (paint, enamel, galvanizing, .

Notes: 1μm (1 micron) = 0.001mm; a The thickness loss values are after the first year of exposure. Losses may reduce over subsequent years. The loss values used for the corrosivity categories are identical to those given in BS EN ISO .

An intumescent paint is a coating that reacts to heat by swelling in a controlled manner to many times its original thickness, producing a carbonaceous char formed by a large number of small bubbles that act as an insulating layer to protect the substrate. . Structural steel column and beam. Clean, dry and free from dust, oil, loose mill .Fire Test Reports: (i) WARRES No.107529&107530&111451/ Loaded I-Beam Sections 1 & 2 hrs. Loaded I-Beam Fire Test Reports. (ii) WARRES No.114048/ Loaded RHS Beam Sections 2 hrs. Loaded RHS-Beam Fire Test Report. (iii) WARRES No.109139&115162&115723 /Short Section Steels 1 & 2 hrs. Indicative Fire Test Reports.pool of metal and holds it there until the weld solidifies. The molten metal is held in place by a ceramic ferrule, which also serves to shield the arc. Figure 3 illustrates a stud with the ceramic ferrule still in place. Testing shows that the weld collar so formed is very important in transmitting shear. The resistances for shear studs in EN .Bond Testing; Thickness Gauges . Theory of Operation for Measuring Metal Thickness through Paint Longitudinal wave sound velocity in steel is typically around 5,900 m/s (0.2320 in./µs), while sound velocity in paint and similar coatings is .

shall be available at the painting facility. 2.1 American Association of State Highway and Transportation Officials (AASHTO) 2.1.1 AASHTO M 160, Standard Specification for General Requirements for Rolled Steel Plates, Shapes, Steel Pilings, and Bars for Structural Use 2.1.2 AASHTO M 300, Standard Specification for Inorganic Zinc-Rich Primer

steel construction paint requirements

Topic: Dry film Thickness (DFT) Test🔍 Welcome to Construction Engineering Tips! In this in-depth video, we explore the essential technique of Dry Film Thick. The required thickness of intumescent paint depends on several factors: Steel Section Size: The size and complexity of the steel sections play a crucial role in determining the thickness of the coating. Larger or more complex structural elements often require a thicker layer of intumescent paint to ensure they are well protected in a fire.

Consistent performance benchmarking testing capabilities for professional PC users. . Typical coating application thickness is between 0.03 and 0.50 inches; . The structural element (beam, joist, column, roof assembly or floor-ceiling assembly) surface must be properly prepared for the material application. .the ability of the steel to carry the design load, it is possible that a premature failure of the building or assembly therein may occur, thereby jeopardizing the safety of the inhabitants, first responders or adjacent properties. Industry standards and test methods have been developed to validate that the installed SFRMs and IFRMs conform withThe following specification shall be used for painting of structural steel work. 9 PAINTING ON STRUCTURAL STEEL Painting for structural members shall be one or more coat of Red Oxide primer and 2 or more coats of Synthetic Enamel Paint of approved brand having thickness of 90-100 micron DFT at site.

1000 on a refractometer means

Resultado da São eles: Claro, Vivo, TIM, Oi, Nextel, CTBC, Telemig, Brasil Telecom e Sercomtel. Acese já o Torpedo Gratuito e envie Oi torpedo e para outras .

test thickness of paint on a steel column|coating thickness measurement example